Navigation

Navigation

- Home

- About Beck Engineering

- Services

- Simulation Aided Engineering

- Mine Scale Modelling

- Hydro-Mechanical Coupling

- Multi Scale and Multi Physics Simulations

- Caving Initiation, Propagation and Subsidence

- Coal Mine Simulation

- Dynamic Simulation

- Groundwater in Mining Applications

- Ground Support

- Underground Deformation Mapping

- Expert Assistance and Peer Review

- Mining and Reservoir Induced Seismicity

- Oil and Gas

- Open Pits

- Shaft Sinking and Shaft Deformation

- Stoping, Cut and Fill and other underground methods

- Large Excavation Engineering

- Research & Rock Mechanics

- Collaboration

- Downloads

-

Simulation Aided Engineering

BE produces high fidelity discontinuum, non-linear models for mining, civil and oil and gas engineering. We work with our clients to re-engineer their designs if needed, or else, we can provide high resolution results for on-site use. The model database can be interrogated,...

Read More -

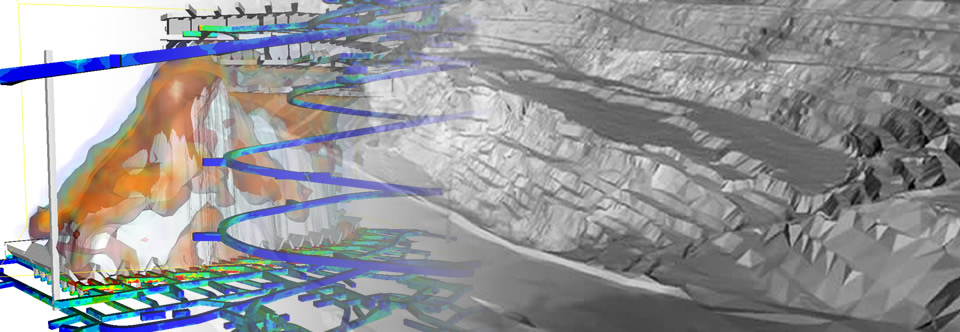

Mine Scale Modelling

BE can simulate your entire mine, incorporating structures and discontinuities from the smallest to largest length scales. Our services include: Large, 3D mine-scale non-linear, strain-softening discontinuum finite element (FE) models using higher-order elements. Simulation of...

Read More -

Stoping, Cut and Fill and other underground methods

BE specialises in application of advanced, multi-scale, discontinuum modelling tools to simulate open stope overbreak, access conditions, filling and induced seismicity. We are the only provider of probabilistic simulation for stope overbreak potential. Our open stoping...

Read More -

Shaft Sinking and Shaft Deformation

BE specialises in shaft deformation management. We work with mines across the globe that have highly deformed shafts to plan extraction and maintain their shafts. We provide: reliable, accurate, realistic deformation forecasting with multi-scale discontinuum finite element...

Read More -

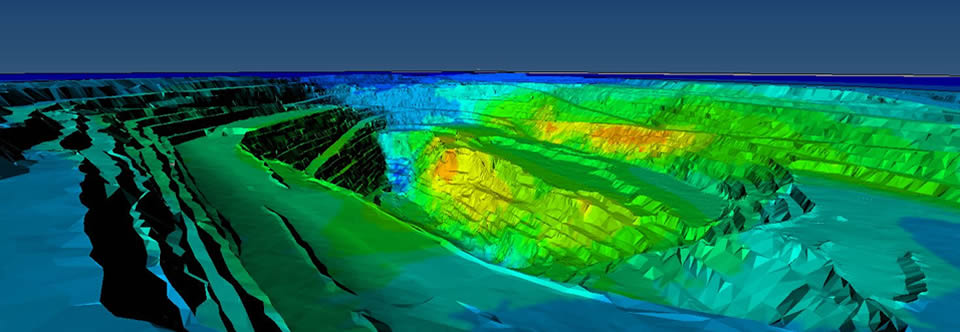

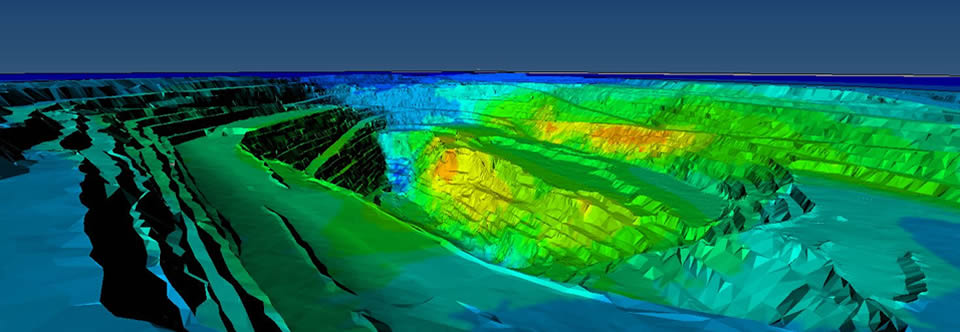

Open Pits

There is a trend for open pits to be mined to greater depths than before. The greater depths are leading to higher underlying strains in the slope and failures arising from rock mass instability have become more prominent. These failures include instabilities resulting from the...

Read More -

Oil and Gas

BE undertakes automatically fully coupled hydro-mechanical analyses: one-way or two-way fully coupled, field scale, 3D, discontinuum models flow on discontinuities non-linear hydrogeological models – rock mass damage and fault movement changes the hydrogeological...

Read More -

Mining and Reservoir Induced Seismicity

BE’s strain-softening, dilatant LR2 finite element models have been demonstrated to reliably forecast seismogenic potential at operations across the world, using correlations between simulated energy release, fault slip and the likelihood of event occurrence (event...

Read More -

Expert Assistance and Peer Review

BE’s mining engineers are experienced expert witnesses and provide strategic technical advice on projects and operating mines to boards and decision makers across the world. For more information contact Dr David Beck or Dr Alex...

Read More -

Ground Support

To reliably simulate the ground support response, ground deformation must be captured accurately, which means that the mechanisms of rockmass damage, dilation and deterioration must first be correctly simulated. BE uses a multi-scale, discontinuum approach to improve the...

Read More -

Dynamic Simulation

Beck Engineering simulates the cumulative effects of repeated dynamic loading by blasts, seismic events and earthquakes on stability, damage and deformation of built structures and excavations. We use 3d, strain softening geological models, incorporating built structures,...

Read More -

Coal Mine Simulation

BE introduced mine scale discontinuum 3d modelling to the coal industry as a new standard for everyday modelling tasks. This was a step change in model resolution for coal mine simulation: Transparent workflow and results: BE makes all results, inputs and assumptions available...

Read More -

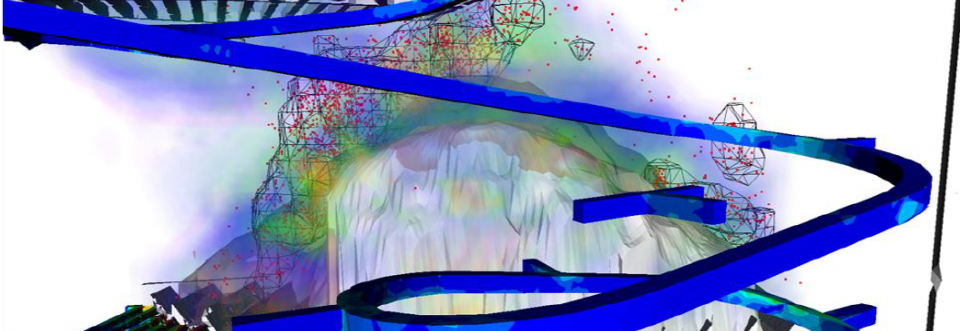

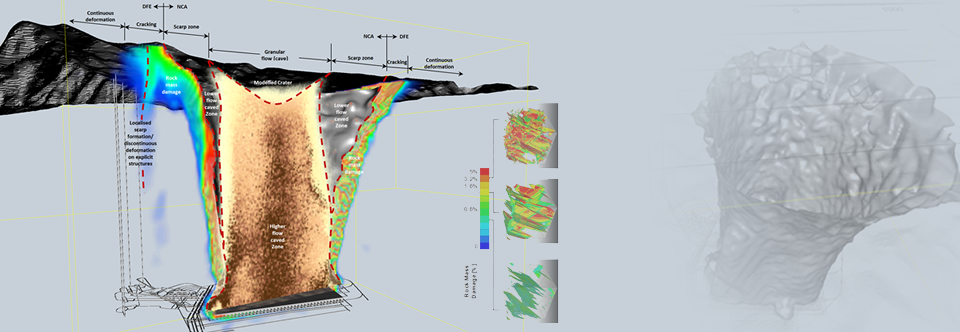

Caving Initiation, Propagation and Subsidence

To better estimate the likely performance of caves, a tool that properly accounted for the physical coupling of the caved material to the un-caved rock mass and the draw schedule, driven by the known physics of both parts of the problem was needed. No such tool was...

Read More -

Large Excavation Engineering

With BEs constitutive models and higher order, multi‐scale approaches, almost any damage and dilation mechanism in rock can be replicated. The key to all our modelling is simple, sound modelling practice. Our goal is to replicate the nature, magnitude and extent of measured...

Read More -

Research & Rock Mechanics

Homogenisation & Discrete Fracture Networks BE has conducted extensive research in the area of rock property estimation, rock strength scaling and homogenisation. One technique applied for these tasks is numerical homogenisation. This involves constructing a model of the...

Read More

Beck Engineering is an Australian-based engineering firm that specialises in mining and rock mechanics analysis for the global mining industry.

We apply realistic physics-based simulation methods to forecast the geotechnical performance of underground and open pit mines, across a broad range of mining methods, geotechnical conditions and commodities. Our experienced mining engineers work with our clients to integrate these performance forecasts into practical mine designs, schedules and operating plans.

Beck Engineering shares a common goal with our clients: To design, plan and operate safe, productive and reliable mines.

|

BECK ENGINEERING Pty Ltd ACN 113 083 060 SYDNEY, AUSTRALIA Dr. David Beck +61 412 135 782 BRISBANE, AUSTRALIA +61 448 467 485 BERLIN, GERMANY Applied Mechanics Group +49 30 8507 3699 SANTIAGO, CHILE Eduardo Cordova, Integral Mining +56 95 412 3108 info@beck.engineering |

|

|

Follow us on LinkedIn and visit our company website here. |

© 2024 Beck Engineering Pty Ltd